This made downstream toolpath generation quite a bit easier. Put the interior geometry on a separate layer from the exterior geometry. Firstly, he setup my Rhino model so it had a bounding geometry outlining the stock (OSB 4ft x 8ft, long axis of the machine vertical by convention), as well as The next day, Architecture RPL guru David Costanza was able to give me a few pointers on the correct way to go about using Rhino and MasterCam. Unable to figure these issues out, I called it a day. The other issue, the lead ins/outs (The curved sections where the tool goes up and down), were cutting into different parts of the model.

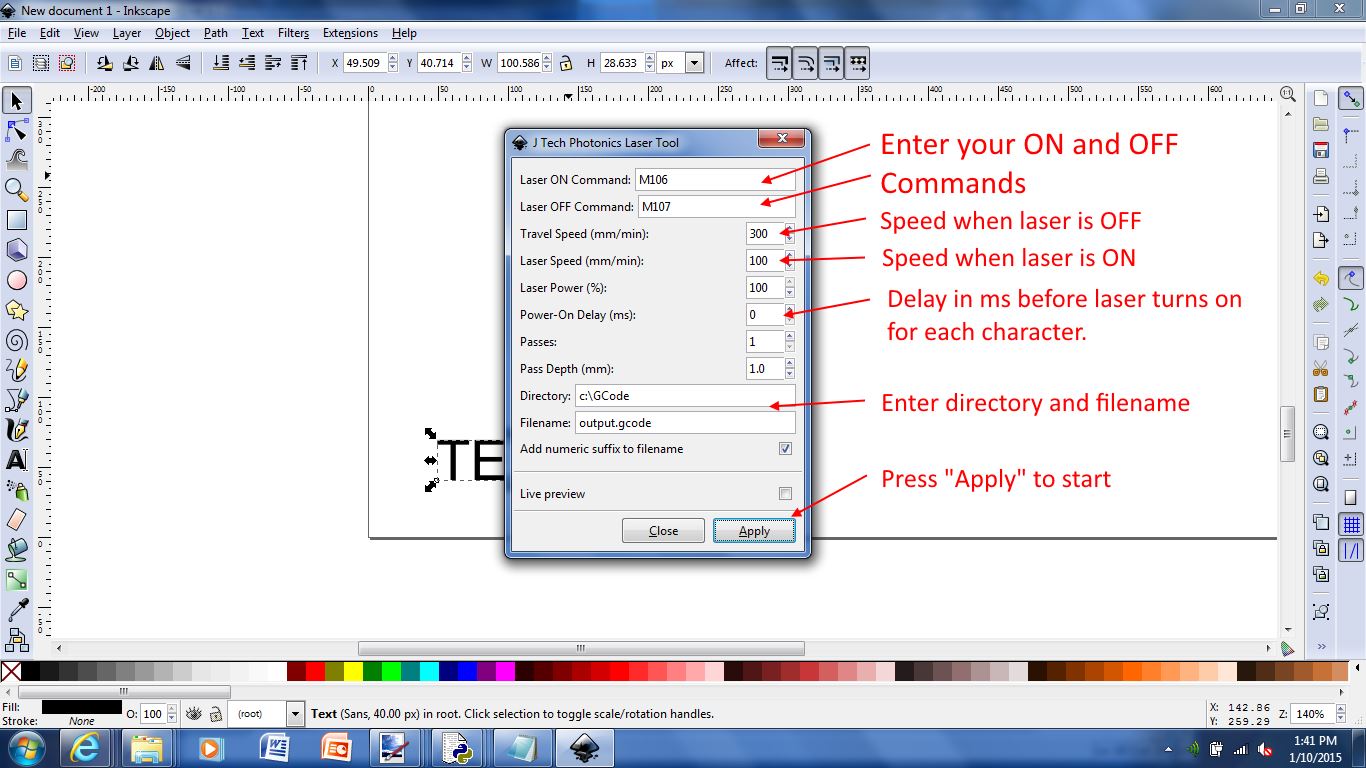

Inkscape gcode toolpath software#

This led to the software thinking the stock started a Z 0.0, and from the simulation I could see the toolpath dragging the tool everywhere

Inkscape gcode toolpath how to#

Firstly, I hadn't yet figured out how to properly specify the height of the stock. But before running this toolpath, I ran into some issues. Had I actually used this toolpath, it would have been pretty crappy results likely, as the lack of a finishing pass means the corners and insets would

They both used tool #1 (0.375" compression tool).

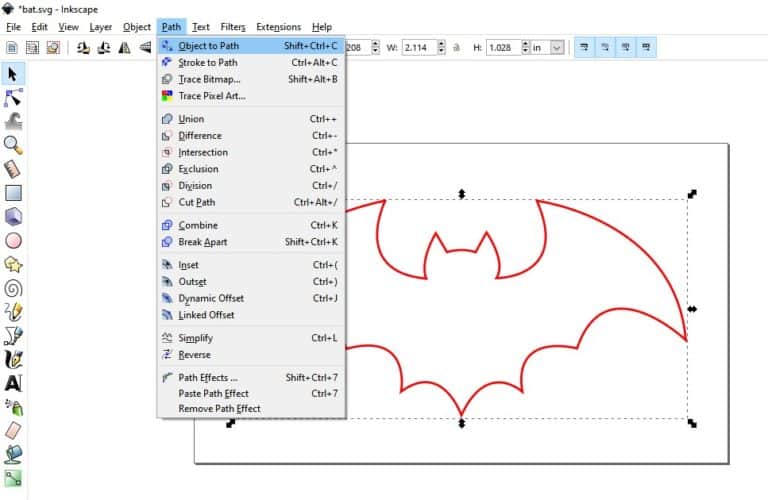

I made two rough cut toolpaths, one for the exterior of the geometry, and one for the internal cutouts. The image above shows my attempt first attempt at designing a MasterCam toolpath. MasterCam is a very powerful, and incredibly obtuse piece of software. This was really where the majority of my time on the project this week was spent.

I then transfered my model from Rhino to MasterCam. The vertical structure comes expectedly from the "vertical beams" which pressfit into the lengthwise beams, thereby connecting two faces to make a box. A short description of the design: It is a box, the top or bottom face is defined by 2x "lengthwise beams", 2x "widthwise beams",Ĥx intersecting "cross beams", which pressfit together. I put the cloning trick Neil demonstrated for the laser cut pressfit assignment to good use again, this allowed me to easily propgate changes Yet again I used Inkscape for my modeling tool, as at this point I know all its tricks and nothing necessarily called for 3D design. That is actually a pretty elegant solution. Okay, thats my somewhat justification for this design, but in actuality it was more just practice making something big. Life stages, maybe you could collect enough moss for detailed study of its metabolites throughout the lifecycle. The idea for the design was: if you could grow a lot moss on large vertical surfaces, and it would pass through all the However, the disorganized cells from liquid culture isn't too appealing if you want to study natural metabolites, as these might only be present in certain tissues etc. Where it will go through its entire lifecycle (leafy structure etc.), or in largescale liquid culture, where it remains as disorganized cells. Right now, you can grow moss at a smallish scale on petri dishes, I'm interested in studying the metabolites of moss, but this requires a *lot* of biomass. Moss is an interesting and somewhat understudied model organism. In short, I expanded a bit upon my week 1 idea to tryĪnd make a specialized moss growing structure. So I wasn't able to get a good single image of my sketching. Unfortunately OneNote likes to divide things into pages when you try to export (it is a note taking program after all), I started out designing this week by sketching up some ideas in OneNote.

0 kommentar(er)

0 kommentar(er)